50% Response rate

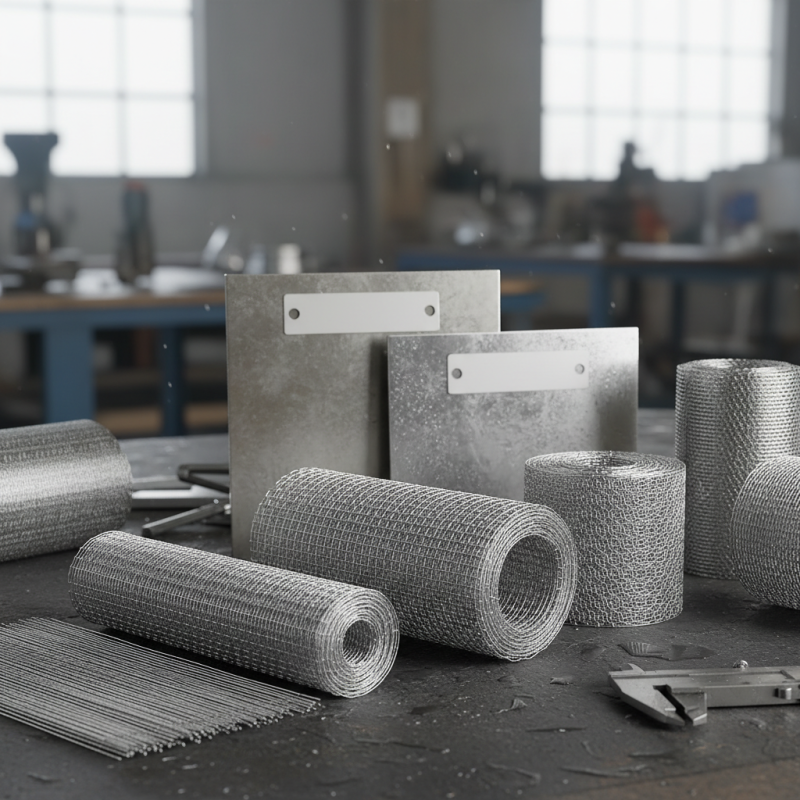

How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

Choosing the right stainless steel wire mesh can be a daunting task. It involves understanding specific requirements for your project. This material is versatile and durable, found in numerous applications like filtration, security, and architecture.

Consider the wire diameter and mesh size. These factors greatly influence strength and functionality. A finer mesh provides better filtration but may lack structural integrity. On the other hand, thicker wires enhance durability but may limit fluid flow.

Furthermore, think about the type of stainless steel. Different grades offer varying corrosion resistance and temperature tolerance. The choice may depend on environmental conditions. While selecting, be mindful of your project’s unique needs and potential challenges. Finding the perfect stainless steel wire mesh is a process filled with questions and uncertainties.

Understanding the Basics of Stainless Steel Wire Mesh

Stainless steel wire mesh is versatile. It is used in various applications, from industrial to domestic. Understanding its basics is crucial when selecting the right type for your needs.

The mesh is made from stainless steel strands. It varies in thickness and weave pattern. Common weaves include plain, twill, and satin. Each type impacts strength and flexibility. For example, twill weave offers more durability. However, plain weave is often more affordable.

Before making a choice, consider your specific requirements. The mesh's gauge affects its strength. A finer mesh might block smaller particles but could be less durable. Think about your long-term use. Sometimes, the cheapest option may not be the best investment. When in doubt, gathering samples can help you visualize the differences better. Don't rush this decision; it requires careful thought and consideration.

Identifying Your Specific Application Requirements

Choosing the right stainless steel wire mesh requires careful consideration. Different applications have unique needs. Start by identifying the specific requirements of your project. What environment will the mesh be used in? Will it face exposure to chemicals or extreme temperatures? This can greatly affect your choice.

Next, consider the mesh opening size. It determines what can pass through. For filtration, a finer mesh may be necessary. However, if strength is the priority, larger openings might be better. Think about the material thickness, too. A thicker wire can enhance durability but may also add weight. Sometimes, a compromise is needed.

Also, don’t forget about the weave type. Various weaves offer different benefits. A twill weave can provide flexibility but may reduce strength. Experimenting with options can lead to unexpected results. You might find that a less common choice meets your needs more effectively. Reflecting on these aspects will guide you to a suitable decision.

Evaluating Different Wire Diameters and Mesh Sizes

When selecting stainless steel wire mesh, understanding wire diameters and mesh sizes is crucial. Different applications require specific characteristics. Thin wires with smaller diameters can create tighter, finer meshes. This is ideal for applications that need precise filtration. For example, a study by the Industrial Fabrics Association International noted that a mesh with a 0.002-inch diameter can filter particles down to 50 microns effectively.

Conversely, larger wire diameters support heavier loads. A thicker wire can handle more pressure without deforming. In heavy-duty applications, such as in construction or industrial settings, larger openings are often preferred. Data from the American Society for Testing and Materials emphasizes that using a 0.047-inch diameter wire yields a mesh that can withstand significant tension. Mesh sizes must balance between strength and filtration ability, a challenging consideration in design.

Working with wire diameters and mesh sizes isn’t foolproof. Smaller mesh sizes trap particles better but can clog easily, requiring more maintenance. Larger meshes allow faster flow but may compromise filtration quality. Understanding the trade-offs can guide better choices, but there is often no clear winner. Users should reflect on specific needs and conditions to make informed decisions.

How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

| Wire Diameter (mm) | Mesh Size (Inches) | Open Area (%) | Applications |

|---|---|---|---|

| 0.5 | 4 x 4 | 56 | Filtration, Grating |

| 1.0 | 8 x 8 | 52 | Safety Screens, Railing |

| 1.5 | 10 x 10 | 48 | Industrial Use, Sifting |

| 2.0 | 20 x 20 | 40 | Construction, Ventilation |

| 3.0 | 30 x 30 | 35 | Animal Enclosures, Security |

Considering Corrosion Resistance and Durability Factors

When selecting stainless steel wire mesh, corrosion resistance and durability are essential. Various grades of stainless steel offer different levels of resistance. For instance, Type 304 stainless steel is commonly used due to its good resistance to corrosion in various environments. However, under harsh conditions, Type 316 stainless steel is preferred. It contains molybdenum, providing better protection against chlorides.

**Tips:** Always analyze your specific environment. If salt or chemicals are involved, opt for higher-grade materials. Regular maintenance can extend the mesh's lifespan.

Another factor to consider is the wire diameter. Thicker wires generally provide better durability but may limit flexibility. According to industry reports, wire mesh with a diameter of 0.040 inches to 0.062 inches balances strength and adaptability well. However, this balance isn't perfect for every situation. You must determine if flexibility is as crucial as strength for your application.

**Tips:** Conduct strength tests on various thicknesses. Consider how the mesh will be used. Understanding these elements is key to making an informed decision. Remember, there’s no one-size-fits-all solution in stainless steel mesh selection.

Corrosion Resistance and Durability of Stainless Steel Wire Mesh

Comparing Different Stainless Steel Grades for Your Needs

When selecting the right stainless steel wire mesh, understanding the grades available is crucial. Common grades include 304 and 316. Grade 304 is versatile and widely used in many applications. It has good corrosion resistance and can handle moderate environments well. However, it may not be the best choice for marine environments.

On the other hand, grade 316 offers superior resistance to salt and chemicals. It is often used in more challenging environments, including coastal areas. While 316 is more expensive, it may save you costs in the long run due to its durability. Depending on your project, weighing these benefits is vital.

If you’re uncertain, sometimes it's best to consult an expert. Your specific needs can influence the choice dramatically. Don’t rush. Take your time to analyze different options. This careful consideration can lead to better outcomes. Choosing the right material is not just about cost; it is about performance and longevity.