50% Response rate

How to Choose the Right Excavator Saw Head for Your Project?

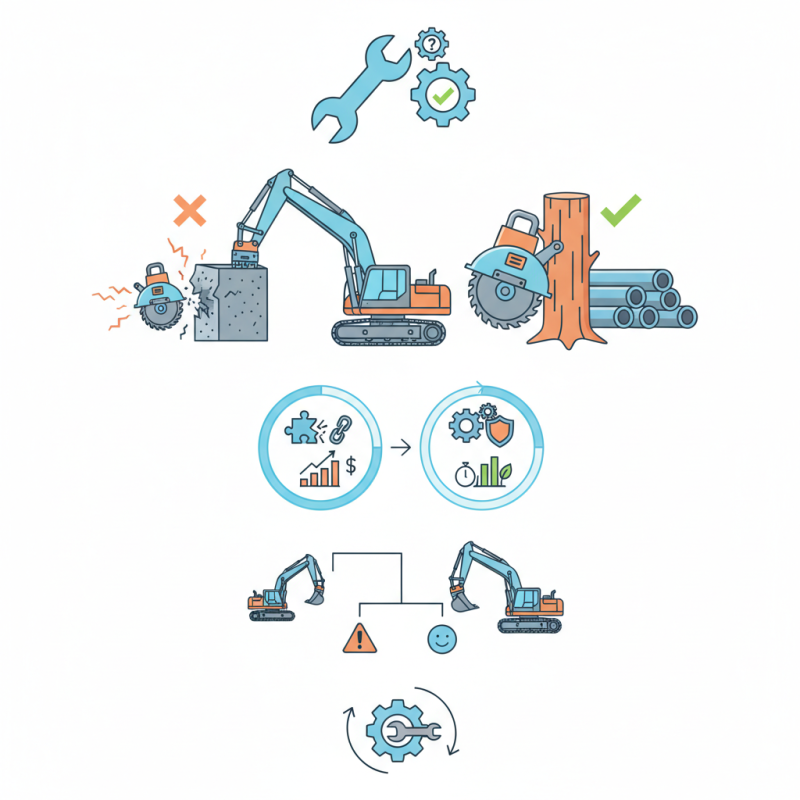

Choosing the right Excavator Saw Head is crucial for any construction or demolition project. A study by the Construction Equipment Manufacturers Association (CEMA) indicates that 70% of project delays are due to equipment mismatches. This highlights the need for careful selection. The Excavator Saw Head should be compatible with your specific excavator model and the material you will be cutting.

Expert Mark Anderson, a well-known industry leader, states, “Selecting the appropriate Excavator Saw Head can dramatically improve efficiency.” His insight resonates in field reports showing that the right tools increase productivity by up to 25%. Using the wrong attachment may lead to inefficiencies, increased costs, and safety hazards on site.

Moreover, many operators overlook the importance of maintenance and compatibility. Some Excavator Saw Heads can wear out quickly if they are not suited for the job. Always consider the specifications and manufacturer recommendations. Reflecting on these factors helps prevent costly mistakes and ensures a smoother workflow.

Understanding Excavator Saw Heads: Types and Applications

Excavator saw heads are crucial for various projects. Understanding their types helps in selecting the right one. There are primarily two types: diamond saws and hydraulic saws. Diamond saws excel in cutting hard surfaces. They create clean and precise cuts. Hydraulic saws, on the other hand, provide more power for tough conditions.

Each type has specific applications. Diamond saws are perfect for asphalt and concrete. They are ideal for small to medium projects. However, they can struggle with thicker materials. Hydraulic saws work well in heavy demolition. They can handle larger jobs with ease. Yet, they may not be suitable for delicate tasks.

Choosing the right saw head can be challenging. Consider factors like project size and material type. Don't overlook the potential for misuse. Choosing an incompatible saw could lead to inefficiencies. Reflect on the requirements before making a choice. It's vital to gauge the limitations of each type. A well-considered choice can lead to better results.

Key Factors to Consider When Choosing an Excavator Saw Head

Choosing the right excavator saw head is crucial for project success. Several key factors play a significant role in this decision. First, consider the type of materials you will cut. Different saw heads perform better with specific materials. For example, concrete and wood require different cutting techniques and blade designs.

Another important factor is the size of your excavator. A bigger excavator can handle larger saw heads, which increases efficiency. However, using an oversized saw head on a smaller excavator may cause problems. It's essential to ensure compatibility between the machine and the saw head. Check the hydraulic requirements and fit before making a choice.

You should also evaluate your project’s specific demands. Are you facing tight spaces or complex cuts? Some saw heads excel in maneuverability, while others are designed for heavy-duty tasks. Balancing power and precision is not easy. It may take time to find the perfect fit. Lastly, remember that frequent maintenance is essential. Neglecting care can lead to inadequate performance and unexpected costs.

Excavator Saw Head Selection Factors

Compatibility with Excavator Models: A Crucial Aspect

Choosing the right excavator saw head requires careful consideration of compatibility. Each excavator model has specific requirements. The saw head must match the hydraulic system of the excavator. This ensures efficient operation and optimal performance. Misalignment can lead to equipment failure. Always check the specifications before making a decision.

There are various excavator models on the market, and not all saw heads fit every model. A mismatch can cause issues during operation. Some users may find it challenging to understand compatibility charts. It’s essential to consult with experts or do thorough research. This step can prevent costly mistakes later on.

Incompatibility can lead to operational delays. It may also lead to unexpected costs. Reassessing the compatibility before making a purchase might save time and money. Consider the application for which the saw head will be used. Parameters like weight and cutting capacity play a significant role. Always choose wisely to ensure project success.

How to Choose the Right Excavator Saw Head for Your Project? - Compatibility with Excavator Models: A Crucial Aspect

| Excavator Model | Saw Head Compatibility | Weight of Saw Head (kg) | Blade Type | Recommended Applications |

|---|---|---|---|---|

| Cat 320 | Compatible | 150 | Diamond Blade | Concrete Cutting |

| Hitachi ZX350 | Compatible | 200 | Tungsten Carbide Blade | Metal Cutting |

| Komatsu PC210 | Not Compatible | N/A | N/A | N/A |

| Bobcat E165 | Compatible | 100 | Chain Saw Blade | Tree Trimming |

| Volvo EC950 | Compatible | 250 | Segmented Blade | Asphalt Cutting |

Evaluating Cutting Performance and Efficiency of Saw Heads

When selecting an excavator saw head, cutting performance is crucial. A saw head must effectively cut through various materials. Materials like concrete and steel provide different challenges. A saw head designed for tough materials should have distinct features. Blade shape and tooth configuration play key roles in performance. The right combination improves efficiency and reduces downtime.

Efficiency often relies on the blade speed and power. Some saw heads operate better at higher speeds, yielding cleaner cuts. Others may require slower speeds to maximize accuracy and minimize wear. It’s essential to consider the materials you'll encounter. Cutting too quickly might cause overheating or premature wear. Observing the wear patterns can highlight areas for improvement.

Evaluating performance in real-world scenarios is valuable. Each project might reveal new insights into efficiency. If a saw head struggles with a certain material, reflect on the choice. Adjusting either the saw head or cutting technique may enhance results. Consider how different environments affect cutting speed. Dust, moisture, and temperature can all influence performance outcomes.

Maintenance Tips for Prolonging Excavator Saw Head Lifespan

Maintaining your excavator saw head is crucial for optimal performance. Regular maintenance can extend its lifespan significantly. Inspect the saw head frequently for any wear and tear. A small crack can lead to bigger issues later. Clean the blades regularly to avoid buildup that can affect cutting efficiency.

When using the saw head, be mindful of how you operate it. Aggressive cuts can cause unnecessary stress. Try to avoid continuous heavy usage without breaks. This can lead to overheating and reduce the tool's effectiveness. Properly lubricate the moving parts to keep them functioning smoothly.

Don't overlook storing your excavator saw head properly. A dry and safe environment is key. Exposure to moisture can lead to rust. Consider using protective covers when not in use. Ultimately, paying attention to these details can save you time and money in the long run.