50% Response rate

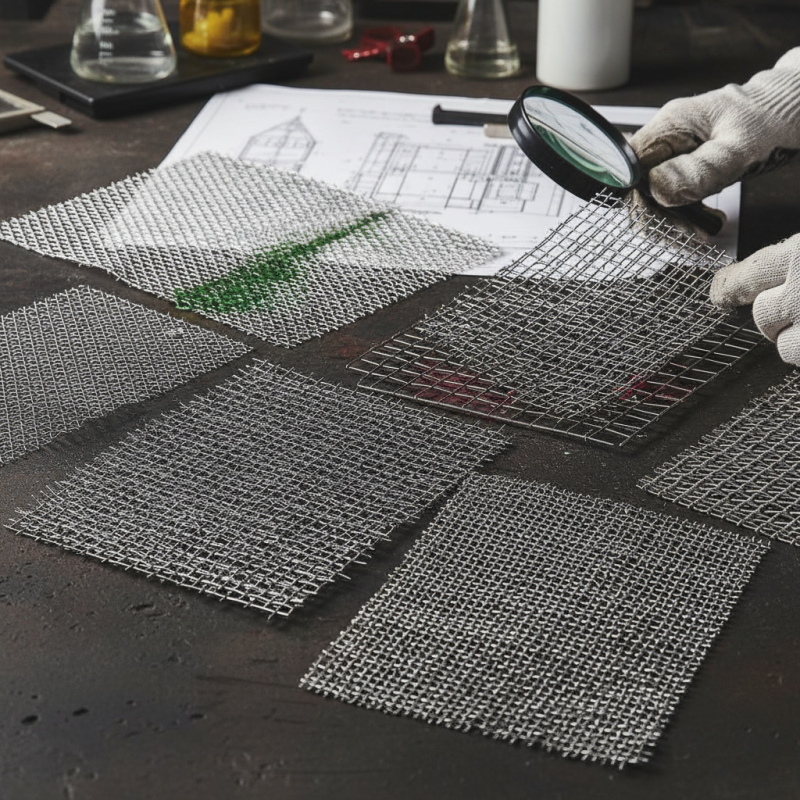

How to Choose the Right Stainless Steel Woven Wire Mesh?

Choosing the right stainless steel woven wire mesh can be challenging. This material is widely used in various industries, from construction to food processing. Each application demands specific qualities.

stainless steel woven wire mesh offers durability, resistance to corrosion, and versatility. However, not all meshes are created equal. Factors such as wire diameter, aperture size, and weave pattern significantly affect performance. Be mindful of these details when selecting a mesh.

It’s essential to think about your specific needs. Consider the environment where the mesh will be used. Will it face extreme temperatures or chemicals? Reflect on these questions. A poor choice could lead to costly repairs or replacements. Making an informed decision can truly enhance your project's success.

Understanding the Basics of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is widely used in various applications. Understanding its basics is essential for making informed choices. This mesh is made from stainless steel wires, woven together in different patterns. The structure determines its strength and flexibility. It can be used in filtration, decor, and safety applications.

When choosing mesh, consider the wire diameter and opening size. Thicker wires provide more strength but can be less flexible. Smaller openings allow for finer filtration but may restrict airflow. Visualizing its applications can help clarify these choices. For instance, a tightly woven mesh is ideal for sifting fine particles, while a looser weave may serve better in outdoor fencing.

Recognizing your specific needs is crucial. Some may prioritize durability over aesthetic appeal. Others might need balance between strength and visibility. Finding the right stainless steel woven wire mesh requires trial and error. It's okay to make mistakes while navigating through options. The goal is to gather knowledge and improve your decisions.

Understanding the Various Applications of Stainless Steel Woven Wire Mesh

Key Factors to Consider When Selecting Stainless Steel Wire Mesh

Choosing the right stainless steel woven wire mesh involves considering several key factors. The application is crucial. Is it for filtering, sieving, or reinforcement? Different needs require different mesh types. For example, fine mesh works well for filtration, while coarser meshes are better for structural support.

Next, evaluate the wire diameter and mesh count. A thicker wire increases durability but may reduce flexibility. A higher mesh count means finer filter capabilities but can also impact flow rate. It’s essential to find a balance based on your requirements.

Think about the environmental conditions too. Will the mesh face exposure to chemicals or extreme temperatures? Corrosion resistance is vital in these cases. Testing different prototypes could help identify the most suitable option. Don’t overlook installation ease either. Some meshes can be tricky to fit, leading to installation challenges.

Types of Stainless Steel Woven Wire Mesh and Their Applications

Stainless steel woven wire mesh comes in various types. Each type has unique features and applications. One common type is plain weave. This mesh is versatile and used in filters, sieves, and reinforcement. It provides moderate durability and support.

Another popular type is twill weave. This mesh has a tighter weave, making it stronger and more resistant to wear. It’s ideal for applications requiring increased strength, like architectural facades and industrial filters. The design allows for better airflow as well.

When selecting a type, consider the application. Think about the environment and the mesh's exposure to chemicals. Small details matter. For instance, corrosive environments may require higher grade stainless steel.

Tips: Choose a mesh with the right weave pattern. Don’t overlook mesh openings. They affect performance. Also, assess the wire diameter for durability. Testing in real conditions can reveal weaknesses too. Remember, it's okay to re-evaluate your choices. What works for one task may not suit another.

Evaluating Mesh Specifications: Wire Diameter and Opening Size

Choosing the right stainless steel woven wire mesh requires careful consideration of its specifications, particularly wire diameter and opening size. Wire diameter greatly influences the mesh strength and durability. A thicker wire offers higher tensile strength. This makes it suitable for demanding applications like filtration and construction. Conversely, a thinner wire can be lighter and easier to work with, but it may compromise strength.

Opening size is equally crucial. It determines what can pass through the mesh. Smaller openings are ideal for fine filtration, while larger openings are better for ventilation and drainage. Evaluating your specific needs is necessary here. Are you focusing on filtration or structural support? Understanding the purpose of the mesh will guide your choice.

**Tips:** Always test samples to see how they perform in your intended application. Consider the environment too; corrosive settings may require specific materials. Reflect on how your choice impacts not just functionality, but also longevity.

Maintenance and Longevity: Caring for Your Stainless Steel Mesh

Maintaining stainless steel woven wire mesh is critical for durability. Regular cleaning helps prevent rust and contamination. It's essential to use mild detergents and avoid abrasive scrubbers. A study from the American Society for Metals indicates that proper maintenance can extend the lifespan of such materials by up to 50%. Keeping the mesh dry also prevents moisture collection.

Inspecting your mesh for wear and damage is vital. Small tears can lead to larger problems if ignored. A report by the Wire Association International shows that neglecting maintenance can reduce the effective life of wire mesh significantly. Pay attention to areas that endure stress; these are more prone to failures. Applying a protective coating may help, but be cautious—overcoating can trap contaminants, leading to corrosion.

How to Choose the Right Stainless Steel Woven Wire Mesh? - Maintenance and Longevity: Caring for Your Stainless Steel Mesh

| Aspect | Description | Tips for Longevity |

|---|---|---|

| Material Type | Different grades of stainless steel such as 304 or 316. | Choose grade 316 for marine applications for better corrosion resistance. |

| Mesh Size | Refers to the number of openings per inch; affects filtration capability. | Select appropriate mesh size based on intended application. |

| Wire Diameter | Thickness of the wire affects strength and durability. | Thicker wires provide greater strength for heavy-duty applications. |

| Surface Finish | Electropolished, passivated, or standard finishes improving durability. | Select electropolished for enhanced corrosion resistance. |

| Cleaning Method | Different methods such as chemical, ultrasonic, or manual cleaning. | Use no abrasive substances to avoid surface damage. |

| Storage Conditions | Environmentally controlled spaces to avoid moisture and contaminants. | Store in a dry, clean area away from corrosive materials. |